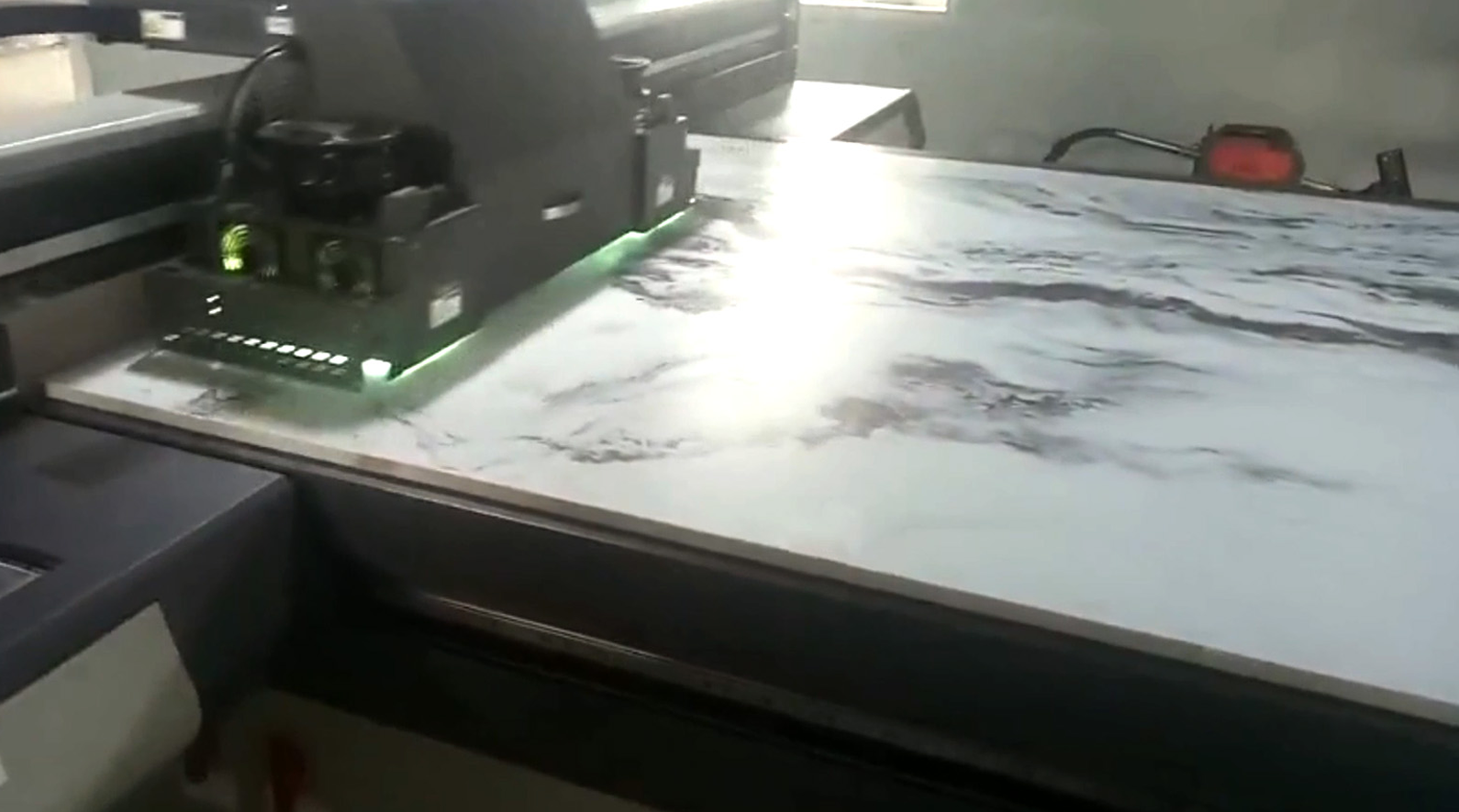

UV curtain coating machine

| UV curtain coating machine SL-TLU | Working width 600mm | Working width 800mm | Working width 1300mm |

| Overall dimensions(length*width*height) | 4200*1430*1350mm | 4200*1630*1350mm | 6200/5000*2130*1350mm |

| Estimated weight | 850kg | 1000kg | 1500kg |

| MAX working thickness | 100mm | 100mm | 100mm |

| MIN working length | 300mm | 300mm | 300mm |

| Working speed | 0-110m/min | 0-110m/min | 0-110m/min |

| Full power | 3.7kw+4kw 380V 50HZ 3P | 3.7kw+4kw 380V 50HZ 3P | 4.4kw+4kw 380V 50HZ 3P |

| Conveyor power | 1.5kw | 1.5kw | 2.2kw |

| Pump power | 2.2kw | 2.2kw | 2.2kw |

| UV Paint pump heating box(size/weight/power) | 1850*1050*1350mm, 150kg, 4kw | ||

| Electric motor | 2sets, UNIS from China | ||

| Frequency Converter | 2sets, DELTA from Taiwan, China | ||

| Electrical appliance | Chint from China | ||

| Conveyor | H850mm, T3mm, UV corrosion resistance belt, Ammerraal from Holland | ||

| Working direction | Right to left | ||

| Knife bit | Aluminum alloy | ||

| Control | Multi-function button control panel, Chinese and English | ||

| One pass coating volume | UV 70g~200g/m2 | ||

| Paint recycling volume | UV Over 40mm than pump plate | ||

-

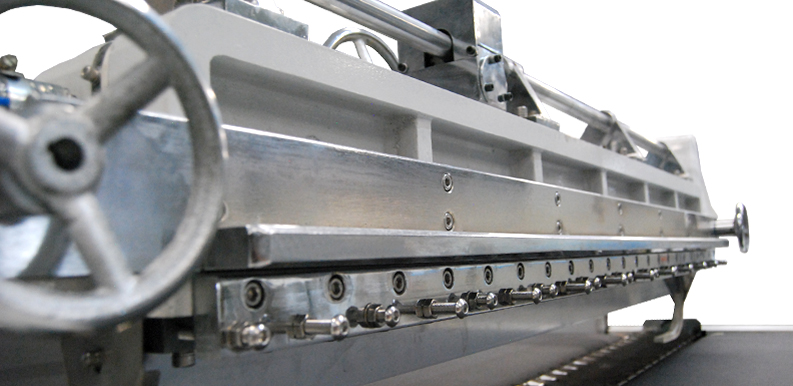

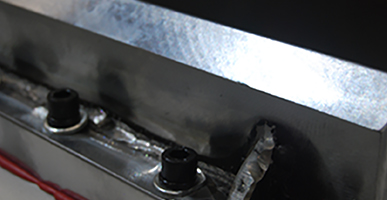

Flip-style knife bit body

-

Aluminum alloy knife bit

-

Large knife paint cavity

-

UV paint multi-filter heating box

-

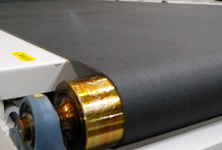

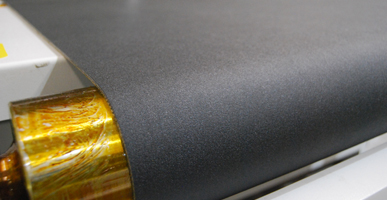

Expert UV corrosion resistance belt

-

Mechanical flip-style knife bit

· Main knife body apply mechanical flip-style tool bit instead of traditional air cylinder type.· Knife apply aluminum alloy material in stead of steel that has better thermal conductance ensure keep shape make even paint stream waterfall.· Adjust more accurately than controlled by air cylinder ensure smooth paint more thick or less.· More crew on knife ensure adjust the coating thickness more accurately especially for wide coating· Larger knife paint cavity is able to support more flow paint

-

-

T6 heat treatment process

T6 is international standard process for Aluminum alloy which will enhance its strength and compact.

-

Surface planish process

Automatic planish machine ensure the knife surface extreme even, keep wider coating paint thickness same.

-

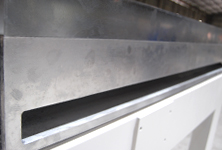

Surface electroplating process

The main parts of curtain knife use electroplating technical avoid of rusting ensure long time working.

-

Paint heating filter box

Stainless steel filter box with seven different degree make more and longer paint stream loop ensure remove air bubble or any impurity.

-

Pump scraw bar

Longer and thicker screw bar is much more stable, reduce the pump swing during work and decrease air bubble come.

-

UV corrosion resistance belt

The expert UV corrosion resistance belt from Holand that prevent UV paint stick on belt pollute back of board and very easily to clean up