Three roller coating machine

| Three roller coating machine SL-TRT | Working width 600mm | Working width 800mm | Working width 1300mm |

| Overall dimensions(length*width*height) | 2500*1550*1750mm | 2500*1750*1750mm | 2500*2250*1750mm |

| Estimated weight | 1300kg | 1500kg | 2200kg |

| MAX working thickness | 100mm | 100mm | 100mm |

| MIN working length | 300mm | 300mm | 300mm |

| Working speed | 0-25m/min | 0-25m/min | 0-25m/min |

| Full power | 8.24kw + 4kw 380V 50HZ 3P | 8.24kw + 4kw 380V 50HZ 3P | 8.24kw + 4kw 380V 50HZ 3P |

| Rubber roller power | 1.5kw*2 | 1.5kw*2 | 1.5kw*2 |

| Stainless steel roller power | 0.75kw*2 | 0.75kw*2 | 0.75kw*2 |

| Stainless steel press roller power | 1.5kw | 1.5kw | 1.5kw |

| Conveyor power | 1.5kw | 1.5kw | 1.5kw |

| Lifting power | 0.37kw*2 | 0.37kw*2 | 0.37kw*2 |

| Paint heating container | 2kw*2 | 2kw*2 | 2kw*2 |

| Electric motor | 8, BMEMB from China | 8, BMEMB from China | 8, BMEMB from China |

| Frequency Converter | 6, DELTA from Taiwan, China | ||

| Electrical appliance | Chint from China | ||

| Main bearing | NSK from Japan | ||

| Application roller | 2, Rubber roller, EPDM, φ205mm, H45 degrees | ||

| Doctor roller | 2, Stainless steel roller, Chroming, φ200mm | ||

| Press roller | 1, Stainless steel roller, Chroming, φ300mm | ||

| Scraper blade | 2, 50*0.203mm, from Sweden | ||

| Conveyor | H850mm, T3mm, PU, Ammerraal from Holland | ||

| Working direction | Right to left | ||

| Paint pump | 2, 0.6mpa, 10L, Vacuum diaphragm pump from Taiwan | ||

| Control system | 1, Shihlin LCD screen, HMI, Chinese and English | ||

| One pass coating volume | UV 25g~70g/m2 | ||

| Paint recycling volume | Over 10kg | ||

-

Roller coating HMI

-

Roller quick disassembly

-

UV putty filling structure

-

Single roller coating structure

-

Roller electric lifting button

-

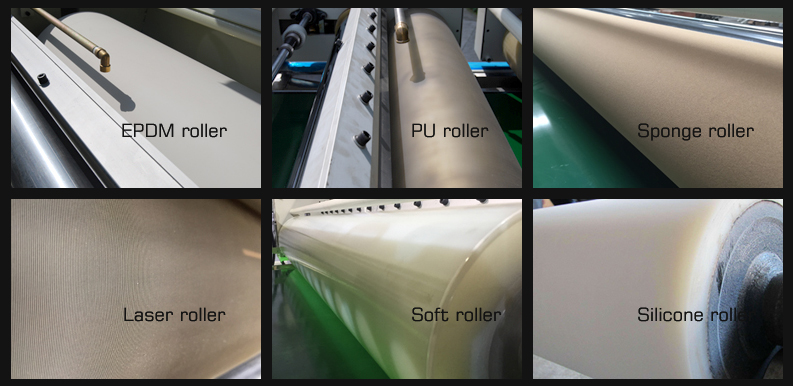

Application roller optional

· We offer most rubber roller optional that expert to meet various paint, board material and coating effect.

· According to different coating thickness demands, you can choose single, double, three or special roller structure.

· Configuration also flexible based on standard machine, customized function is able to design and come true. -

-

Roller quick disassembly

Each rubber roller connect to the motor by NSK bearing with ceramics protective shield. Design quick disassemble structure that convenient to repair or change.

-

Dovetail groove roller lift

The roller apply dovetail groove structure lifting instead of screw drive structure, roller lifting controlled by electric button that stably and easily. Assist by hand wheel ensure more accurate.

-

Push screw compensator

When push the gap between the application rubber roller and doctor steel roller, this screw compensator device can easily adjust balance to ensure the whole gap keep the same.

-

Roller scraper

Sweden thin scraper blade with good flexibility that can remove any impurity and keep even paint on roller during work, uniform screw on the grip ensure stable blade and adjust accurately.

-

Electric motor and reducer

Each roller driven by independent electric motor which stable and durable, with double worm gearing reducer that translate power more smooth and accurately to the roller rotate.

-

Low voltage apparatus

All the electrical low voltage apparatus concentrate orderly and clearly inside the bottom of machine body, far away from working influence and easily to check or maintenance.

-

Two different paint recycling

UV putty filling and primer coating with two independent paint recycling structure and its own paint pump that can work together or separately.

-

Thickness detector

While the thickness of boards over too much than set data, the sensor at the feeding entry will detect and stop the conveyor immediately in case of harm rubber roller.

-

Paint heating container

Warm UV paint get better coating effect, this stainless steel container with temperature controller heating water around 50℃ and keep the liquid recycling UV paint as best situation.

-

Roller water heating system(Option)

In some cold environment, consider add water heating system heating the doctor steel roller keep UV paint warm on the roller for recycling coating, increase the coating effect a lot.