Reciprocating spray painting machine

| Reciprocating spray painting machine | SL-TSWP |

| Overall dimensions(length*width*height) | 5000(+900)*4850*3320mm |

| MAX working width | 1300mm |

| MAX working thickness(include edge) | 40mm |

| MAX working thickness(exclude edges) | 100mm |

| MIN working length | 300mm |

| Estimated weight | 5000kg |

| Full power | 13kw / 14kw 380V 50HZ 3P |

| Average working speed | 1~6m/min |

| The speed of spray painting gun | 1~1.8m/s |

| Paint utilization ratio | 80%—95% |

| Air flow rate | 8000~12000m³/h Air exhuast 3kw, Air inlet 5.5kw |

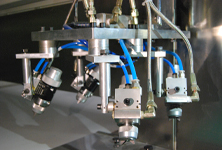

| Spray gun | 8, low pressure mixed air spray gun, GRACO from U.S. |

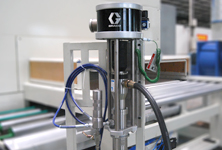

| Paint pump | 1, Merkur bellows plunger type pump, GRACO from U.S., 15:1, 9L |

| Linear guide rail | 2, HIWIN from Taiwan, China |

| Lubrication | 1, Automatic ISHAN from Taiwan, China |

| Automatic scanning system | 2, Bonner screen from America |

| PLC controller | 1, Panasonic PLC, Japan |

| Servo electric motor | 1-2, DELTA from Taiwan, China, 1kw*2 sets or 3kw*1 set |

| Frequency Converter | 2, DELTA from Taiwan, China |

| Electrical appliance | Schneider from Germany, Chint from China. |

| Air cylinder | 0.6mpa, AINTAC from Taiwan, China |

| Light | Fire proof type, LED. 0.05kw |

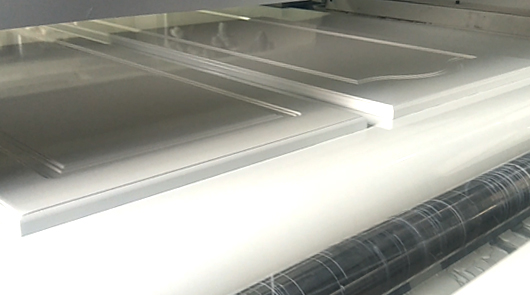

| Conveyor | Left to right, H850mm, T3mm, Corrosion scratch resistant PU belt from Ammerraal, Holland, 1.5kw |

| Belt cleaning pump | 2, Vacuum diaphragm pump, 10L*2 |

| Belt cleaning scraper blade | 2, 0.75kw |

| Steel roller paint scraper blade | 3, 50*0.203mm, from Sweden |

| Control | 1, DELTA LCD screen, HMI, Chinese and English |

-

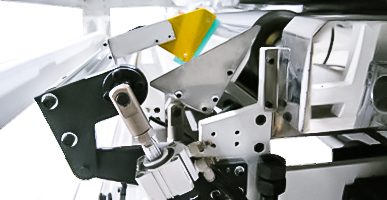

Eight reciprocating spray guns

-

GRACO plunger type pump

-

Automatic PLC control HMI

-

Panasonic PLC controller

-

DELTA servo motor

-

-

-

Automatic scan work piece

Two Bonner light curtain at the entry scan the size and place of work piece, calling right program to control spray range and time, make better utilization efficiency of spraying.

-

Cross reciprocating spraying

Two reciprocating axis apply "Cross" design driven by independent servo motor, ensure spraying more even without miss any part. This motion will deplete paint mist in booth.

-

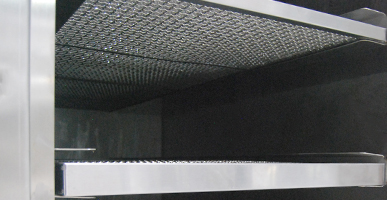

Strong positive air pressure

Large and wider spray booth keep support strong and filtered positive air pressure up to 12,000m3/h, ensure lower paint mist and better spraying effect even for topcoating.

-

Automatic clean spray guns

After work finished, just change the pump pipe into thinner barrel, click the clean then you can leave. Machine will clean the spraying gun, back to original place and shut down by itself.

-

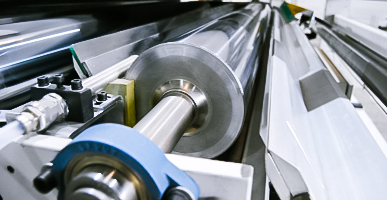

HIWIN quiet straight guid spray rail

HIWIN quiet and heavy load straight guide rail ensure fast spraying action and long distance working easily and smoothly, effective reduce working noise, working stably for 24 hours.

-

Automatic lubricating clocked

The ISHAN lubricating device automatically regular inject lubricant into the rail and flush the used away to ensure the spray rail keep its best without any pause or stop during work.

-

Stainless steel paint mist filter

Inside of the paint storage container with four stainless steel filter layers keep paint mist as liquid drop down and less exhaust away, each filter layer easily to take out clean or change.

-

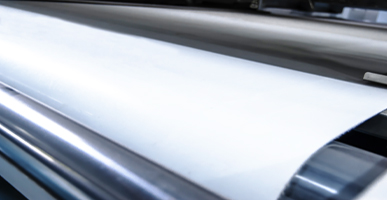

Germany SIEGLING expert belt

Germany SIEGLING top industrial belt with better even surface in large spread area, paint resistance and high quality durable than normal after thousands of times scrap wash

-

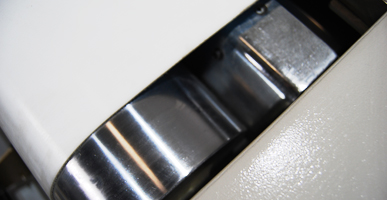

Belt internal scraper cleaning

At two ends of belt conveyor, design blade inside to scrape the supporting stainless steel roller removing any paint ensure the back of belt still keep clean in case of long-term paint pollution.

-

Belt cleaner and scrape paint recycling

This independent cleaning structure with drawer track under the conveyor is able to recycle paint on belt and ensure clean belt in case of staining work piece.

-

Conveyor belt paint scrape recycling

While spray paint on belt and rotate under spraying booth, the stainless steel roller will contact to the belt surface bring paint on itself, then automatic scrape the paint into recycling tank.

-

Conveyor belt cleaning structure

After paint recycling, the belt cleaning device keep pumping thinner on stainless steel roller wash the belt surface and scrape belt ensure it clean and dry as new.