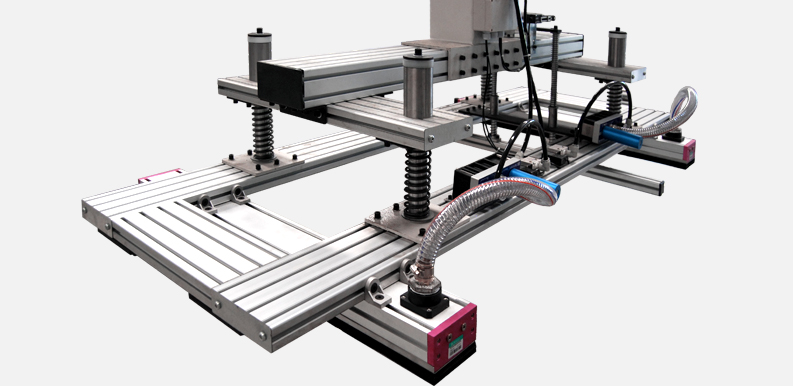

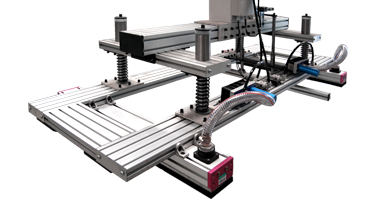

Automatic load and unload machine

| Automatic load and unload machine | SL-FCZ |

| Main body overall dimensions(length*width*height) | 2200*4600*4500mm |

| Conveyor overall dimensions(length*width*height) | 3000*1850*850mm |

| Electric cabinet overall dimensions(length*width*height) | 550*360*1500mm |

| Estimated weight | 2300kg |

| Working length | 1500mm~3000mm |

| Working width | 1000mm~1300mm |

| Full power | 4kw+0.75kw 380V 50HZ 3P |

| Power of Y axis(left and right moving) | 2kw |

| Power of Z axis(lifting moving) | 2kw |

| Conveyor power | 0.75kw |

| Vaccum disc chuck loading weight | Silicone/Sponge 15kg*10sets |

| Vaccum strip chuck loading weight | Sponge 50kg*2sets |

| Air pressure | 0.4-0.6mpa |

| Servo electric motor | 2, DELTA from Taiwan, China |

| PLC | 1, DELTA from Taiwan, China |

| Electrical appliance | Chint from China |

| Linear guide rail | HIWIN from Taiwan, China |

| Vaccum generator | CTM from Japan |

| Solenoid valves | AIRTAC from Taiwan, China |

| Conveyor | Stainless steel rollers, φ60mm, Height 850mm, centring function |

| Control system | DELTA LCD screen, HMI, Chinese and English |

-

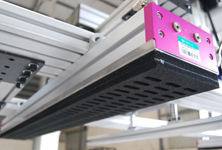

HIWIN linear guide rail

-

Two sponge strip

-

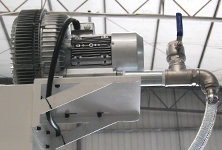

CTM vaccum generator

-

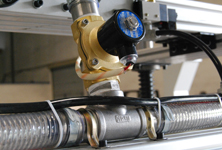

AIRTAC Solenoid valves

-

DELTA servo motor

-

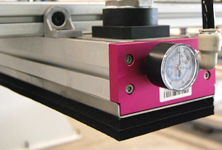

HIWIN linear guide rail

-

Sponge strip with flow indicate

-

Whirlpool fan vaccum generator

-

Solenoid valves switch

-

DELTA servo motor

-

HIWIN linear guide rail

-

Sponge disc

-

CTM vaccum generator

-

AIRTAC Solenoid valves

-

DELTA servo motor

-

HIWIN linear guide rail

-

Silicone disc

-

CTM vaccum generator

-

AIRTAC Solenoid valves

-

DELTA servo motor

-

Rainbow motion trajectory

· Two axis supported by smooth guide rail, PLC and servo motor instead of traditional seimec motor that avoid of working collide without buffer, enable to make the rainbow motion accurately and fast.

· Rainbow motion trajectory not only increase working efficiently, but also avoid of the corner and pause during lifting or translation reduce shaking, with transient active shaking technology when sucking in case of loosing boards.

· Support various sucker satisfied with different materials panel situation and length or width adjustalbe convenient. -

-

Silicone disc sucker

This type as standard basic type with ten silicone disc suckers, suitable to flush panel heavy or light.

-

Sponge disc sucker(Option)

This type as optional with ten sponge disc suckers, suitable to flush, texture or with shallow slots surface panel.

-

Sponge strip sucker(Option)

This type as optional with two sponge strip suckers, suitable to heavy flush, shaped or frame panel.